The second annual Coal Mine Safety Conference was held at the Carbon Events Center. Garth Nielsen is the director of the Office of Coal Mine Safety which is a division in the Utah Labor Commission.

Nielsen said he took a different approach with the conference this year. He is looking at innovative technologies that could be put to use in the coal mining industry.

The first presenter was Ian Houlison from Phoenix by way of Queensland, Australia. He came to America in 2003. He explained the leaps in technology and how they can help the mining industry. His speciality is in gas monitoring instruments. He said many of the instruments being used will monitor gases, but won’t measure them accurately. He said there is a real human error factor with the gas monitoring instruments.

It is also important to know where the gases occur and how to detect them. Some monitors will not only pick-up methane, but other gases as well. Instruments have limitations and they require calibration by someone who knows what they are doing. Some sensors can be poisoned and suffer from cross sensitivity. Over exposure may saturate the instrument. The instruments must be fitted with fresh batteries. Different portions of the mines are susceptible to different pressures and these will affect readings with gas monitoring equipment.

Other influences on monitors are altitude and ventilation. If relative humidity raises it causes oxygen to rise. A typical oxygen censor utilizes a lead or zinc sensing electrolyte and a gold or platinum counter. “There will always be inaccuracies with hand held instruments,” said Houlison.

You want your gas detection devices to not just detect that a gas is there, but let you know how much gas is present.

Houlison stressed the importance of knowing the gases in your mine and how much is there. A history must be kept of gas readings so if the readings change at any point, the miners can be alert to these changes. If your mine is usually 30 parts per million and it jumps to 50 parts then there could be cause for alarm. These statistics need to be accessed easily. Accurate instruments establish a broad base of mine atmosphere. These readings can give early warning of developing situations within a mine. Fires can be prevented if information from these gas detectors is interpreted correctly. Personnel should be trained on their use.

Houlison said he wishes everyone the best in the mining industry. He believes the industry is moving in the right direction with the integration of modern technology. “Looking after your mates, that’s what it’s all about,” said Houlison.

Steve Simmons spoke next and introduced his product called Thermo-Gel. He said Thermo-Gel is a family business and they started by protecting homes from wildfires. The gel substance is sprayed over the house and offers a layer of protection so the structure won’t burn. Their product was used in the 2003 California fires and it was used in Utah this year at the Tooele fire and the fire near Cedar City.

He recently toured a coal mine and thinks the product could be valuable for fires in the mining industry. A fire needs four components to burn and keep burning. Thermo-Gel absorbs heat and it attracts water and also repels water. The product stays cool in extreme heat. It is easy to apply and lasts for several hours. Thermo-Gel acts like a wet blanket and has saved 500 homes and saves lives. The Themo-Gel systems are self-contained because most of the time power is lost in a fire. Simmons said the product sticks to everything but particle board and a freshly stained home. The product washes right off after use. If the product is left to dry then it can be reactivated by applying water. The product is approved by the forest service for use in fire suppression. The product is 100 percent non-toxic and biodegradeable.

A possible use in the mine would be a sprinkling system along a belt line. When Thermo-Gel is sprayed on a fire, it immediately knocks down the flames. The product is also available in fire extinguishers and portable units.

The next presenters were Bradon Bradford and Terri Wright from the Utah Department of Health. They discussed keeping your workforce healthy during the upcoming flu season. Bradford said the flu season runs November-March. The H1N1 flu outbreak has caused 36,000 deaths and 200,000 hospitalizations. The key is reducing transmission so people stay healthy. Flu cases spread quickly if people don’t have any immunity. The flu is spread through respiratory droplets, like coughing and sneezing. These droplets have to enter your body in some way. Usually it comes from touching a contaminated surface and then touching your face then the virus enters and infects. These droplets can live for a number of hours. Flu symptoms come on very rapidly. Cough, aches and pains, runny or stuffy nose, headache, chills and fatigue are some of the symptoms. It is recommended you not return to work until 24 hours after the symptoms subside. It is recommended you see a doctor if you have shortness of breath and difficulty breathing, if your coloring is bluish or for severe vomiting. Going back to work while your are still sick is a risk for other employees.

Wright said it is a myth that the flu was worse in Utah. Utah has a younger population base and Utah health departments do a good job of reporting. In Utah there have been 18 deaths and 302 hospitalized for H1N1. From now on the health departments will just be reporting cases of the flu and won’t distinguish between the seasonal flu and H1N1. Testing to see which virus is present is expensive. Wright encouraged everyone to have their seasonal flu shots. The flu attacks someone weakened in some way. Wright recommended businesses have a plan for sick employees. Everyone should cough into their sleeves and not into their hands. Use hand sanitizers. Keep everything as clean as possible. She encouraged wiping off surfaces and the steering wheels of equipment between operators.

Wright also said companies may need to look at sick leave policies and make sure employees have sufficient recovery time before they return to work.

Nielsen said sometimes miners don’t want to use their sick days for being sick. They would rather use a sick day for something else. But, it’s time to be proactive and wipe off mine phones and equipment between uses. “How hard do you try to have a fully healthy crew. There are some things you can do. Cough properly. Maybe we should bow like the Oriental culture and not shake hands,” said Nielsen.

Wright told the mining companies if any of them would like a worksite flu clinic day the health department would be glad to come to the business for flu shots.

Nielsen told some of the goals for the Office of Coal Mine Safety. They would like to help mines in the event of emergencies. He would like to visit more coal mines in the coming year. The OCMS will work closely with emergency teams in the counties and at the mines. Nielsen plans to visit Local Emergency Planning Committees. He will take the NIMS courses to make sure they are compliant. The OCMS will hold quarterly advisory council meetings and he will push forward recommendations made by the advisory council. Nielsen said he likes to be busy and he is available to take calls 24-7.

Allen Crawford demonstrated and spoke on the Cold Fire product. He said Cold Fire draws the heat out of fire. It is helpful in rescuing people out of burning vehicles. It is used in the car racing industry. Some fire departments are using the Cold Fire product. It will knock down flames and allow rescuers into houses where previously it was too hot to enter. “You can get control of a fire a lot faster with Cold Fire than by using foam. Time is very important in fighting fire. The product is environmentally friendly and bio-degradeable. It knocks out heat and fuel. It adds 10 times the BTUs as tap water. It works to encapsulate the fire,” said Crawford.

The product was tested at an oil refinery fire where 55 gallons of oil were set on fire and Cold Fire extinguished the fire in one minute and 45 seconds, and another benefit is the fire won’t re-ignite when it’s coated with the product. The product can also be used in sprinkling systems and it won’t destroy equipment. Cold Fire creates a thermal barrier. It knocks down fire fast and cools it down. The product works on Class A,B,D and K fires. This product will stick to anything porous and will last until it rains or is washed off.

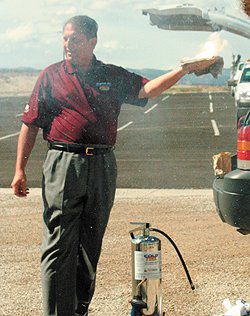

Crawford demonstrated the product by coating his arm and hand with the Cold Fire product and then taking a hand held torch and passing it over his hand and arm. He then coated a towel with Cold Fire and then lit another towel on fire and placed it over the first towel. He held the burning towel and showed how it would not catch the underlying towel on fire. He let a number of audience members hold the towel and they couldn’t feel the fire burning above their hands.

Mine safety conference

"Allen Crawford holds a burning rag. He coats the underlying rag with Cold Fire and his hand isn't touched by the fire."