It isn’t often a coal mine receives recognition for cleaning up a former mine site. Energy West Mining Company has applied for a national award for their reclamation work on the Des-Bee-Dove Mine site. The work was done in three phases; the upper mine, the lower mine, and finally, the sediment pond area below. The mine has been shut down since the mid-1980s and everything is quiet there now. Dennis Oakley who is a senior environmental engineer for Energy West said they have submitted an application with the Division of Oil, Gas and Mining State office. All applications received by the State office are reviewed. Two nominations will then be sent on to the Office of Surface Mining field office. There are nine OSM field offices throughout the nation that cover all 50 states. Each field office will review the nominations and send the final candidates to OSM’s Washington DC Headquarters. Winners will be chosen by a judging panel in Washington DC. Oakley said Energy West has taken groups on tours of the former mine site with favorable results. Oakley asked the Emery County Commission if they would write a letter of support for Energy West for the national award. “We are proud of our project. The mine has had a long history in this area.”

“Mining began around 1898 at the Des-Bee-Dove Mine. It was called the Griffith Mine at the time. In 1936, two men, Edwards and Broderwick, purchased the mine and constructed access to the portals.

“In 1938, the Castle Valley Fuel Company purchased the Griffith Mine from Edwards and Broderick. Also in 1938, the LDS Church purchased coal lands adjacent to the Castle Valley Fuel Company mine and began their own operations. The LDS Church contracted John Frank Killian to operate the “Church Mine”. Killian operated the mine until 1943. Castle Valley Fuel Company operated their mine until 1946.

“The LDS Church purchased the Castle Valley Fuel Company mine in 1946 and re-opened the Church Mine. The combined mining complex became the Deseret Coal Company. Coal from this complex was mined for LDS Church Members under what was called ‘the welfare project’. Coal was mined for church members as well as Brigham Young University, the LDS Hospital and the LDS temple in St. George. Most of the coal went to churches or church members.

“Utah Power and Light acquired the mining complex in 1972. Three room and pillar operations existed: Beehive Mine, Little Dove Mine (Blind Canyon Seam), and Deseret Mine (Hiawatha Seam). Thus, the Des-Bee-Dove Mine complex was formed. UP&L constructed a water line for the mine which was placed on the East side of the canyon so that men could have a bath house. The mining complex was operated nearly continuously until it was idled in 1987,” said Oakley.

Chuck Semborski, Manager of Geology and Exploration, indicated, “a fault line separates the Deer Creek Mine and Wilberg Mine. The Des-Bee-Dove Mine was bound by these two faults. It sits on what is known as a scissor fault where the mining was done across the fault and the coal was recovered.

“At the height of the mine’s day,” Semborski said, “it was running five miner sections and employed 200 miners. The mining there was hampered by faults. After the Wilberg Mine fire, the Des-Bee-Dove Mine was reopened to help supplement coal supplies to the power plant. After the Cottonwood Mine portals were developed, the Des-Bee-Dove was again shut down, this time for good. According to Semborski, “Energy West Mining evaluated the resources there and tried to sell the mine, but after many years they decided to reclaim the mine to its former state. It had been a coal mine for more than 100 years when the reclamation work began.”

Nielson Construction was the contractor for the project and was awarded an Earth Day award from DOGM for their work on the project.

There is one cross over road that wasn’t reclaimed due to gas development and recreation in the area. A cattle trail still runs through the property as well. The local ATV club hopes to one day have an ATV trail through the reclaimed mine-site.

The first step in the reclamation was the assessment of all the components of the project. The steel structures would be removed first and the portals closed. The bathhouse and offices would also be removed. Once demolition was completed, soil resources within the mine site needed to be evaluated. After sufficient soils were identified for reclamation, regrading the site to “approximate original contour” would be completed.

During the soil evaluation process, however; a huge pile of waste coal, or bug dust as they used to call it, was found five feet down and filled the entire valley. An estimated 112,000 tons of coal was dumped there. When this was discovered, the company found it necessary to completely redesign the reclamation plan. Changes to the plan were made to accommodate not only the coal removal from the site, but also to redesign a diversion channel that was to be constructed over the top of this so called “waste” coal pile. The quality of this waste coal was very good.

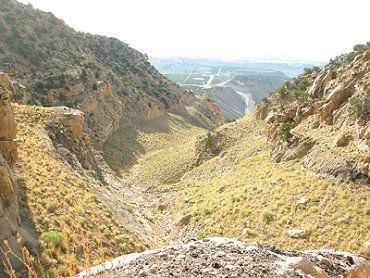

Once the reclamation plans were redesigned and approved by the Division of Oil, Gas, and Mining, reclamation began in 2003. The first phase of the project only included the reclamation of the upper mine. The lower mine was completed the following year and returned to its natural state. “The amount of coal removed from the canyon totaled 108,000 tons,” Oakley said. “The slope work was very challenging for the reclamation workers. They returned the channel to nearly its natural state and while retaining stability of the slopes.”

All reclaimed sites included the replanting of vegetation native to the area. “This is a harsh dry climate, but the project has been successful and the regrowth has done well. The project has already met or exceeded the vegetation standard set by DOGM,” Oakley said. As a requirement of state and federal regulations, liability for the reclamation must be retained by the company for at least 10 years, and until achievement to all reclamation requirements of the State Program are met. Once the site achieves those standards, the bond can be released.

Energy West Mining feels this is a post-mining success story and those stories aren’t often told in a world that considers coal mining a detriment to the environment. This reclamation project proves you can restore a site to where you will never know mining has taken place there.

It was mentioned the coal cars when they came out of the mine, tipped their load of coal over the hill onto the tipple which gave the tipple its name. The company has saved one ore car which they will use later to mark the site of the reclamation project. There is also a rock at the site that has signatures of miners and ranchers who may have worked at the mine.

Oakley mentioned deer and elk are now using the restored habitat for feeding. Everyone commented on the amazing project and how well the reclamation turned out. Commissioner Gary Kofford commented on how the project benefits the county.

Energy West applies for national award

"The reclaimed mine site shows vegetation regrowth and has been returned to its former state before coal mining. Des-Bee-Dove was a coal mine for 100 years."